Are large diameter PVC pipes round? Seems like a silly question – because everyone expects pipe to be round! However, during our recent testing, we were surprised by the results.

PVC pipe isn’t always perfectly round, particularly in large diameter pipes. While this may not seem like a big revelation, it does have potentially serious implications, particularly when being used in large infrastructure projects like underground water mains or sewers.

So Why Isn’t PVC Pipe Always Round?

PVC pipe is formed when the plastic is extruded through a die and cooled in a water bath. The die is manufactured to create perfectly round pipe; however, the pipe it produces may not always cool as expected. There are many factors that can affect pipe shape, including:

- The temperature of the pipe when it exits the extruder, and how quickly it cools

- The die may be imperfect, especially if it’s worn from many years of service

- The extruder machine may need maintenance

- The speed and temperature of the extruder

If there is variation in any of these factors, and there often is, then no two pipes will be identical. So, how do these imperfect pipes pass inspection? PVC pipe that is manufactured for the water industry is typically produced to the American Water Works Association (AWWA) standard C900 or C905. Up until the 2016 version of AWWA C900, there was no requirement to measure for out-of-roundness. There were only requirements for diameter, which didn’t account for pipe shape, allowing it to pass quality control inspection.

Putting to The Pressure Test

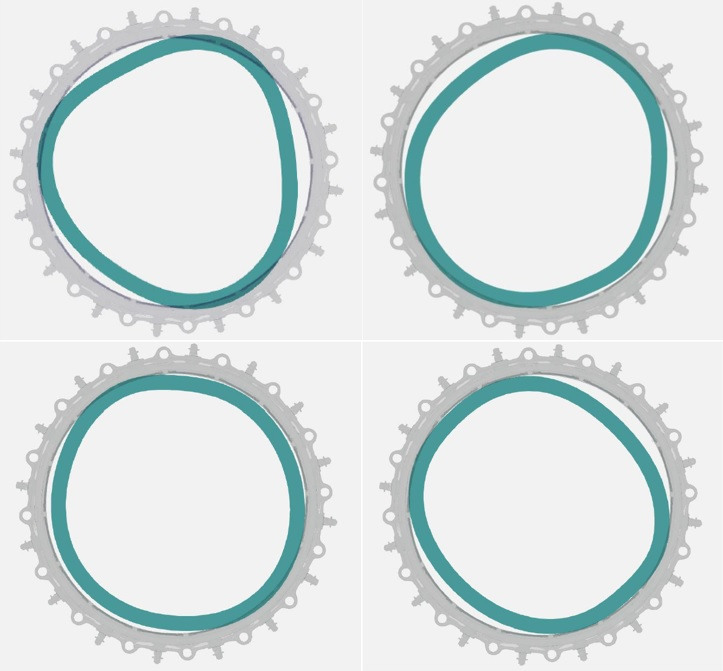

We used a structured blue light 3D scanner to accurately capture the shape of exemplar PVC pipes that we purchased from four different pipe manufacturers in 2018 and 2019. The images show cross-sections of the pipes. The deviation from round of the pipe cross-sections were multiplied by a factor of 10 to exaggerate the pipe shape.

None of the pipes that we scanned are round! And the amount of out-of-roundness varies from pipe to pipe (i.e. from manufacturer to manufacturer).

Why is Pipe Shape Important?

Pipe segments must be joined together. Variance in shape between two adjoining pipe segments can cause issues and affect reliability.

Restraint rings, which are commonly installed at elbows, tees, or end caps, typically use break-away torque bolts that push presser feet into the pipe surface to get grip and resistance to movement. A restraint ring may not create even grab around the non-round pipe and the bolts may not engage the presser feet evenly. This could lead to slippage of the ring and joint failure.

In the worst-case scenario, ring slippage could generate a crack in the pipe which can propagate under pressure leading to disastrous results unknown to the installer.

So, Are Your Pipes a Hazard?

The short answer – it’s very unlikely. While our analysis of pipe shape demonstrates the potential for failure— at a low probability—it may cause issues during installation.

Understanding the risk serves as a reminder to those working and maintaining PVC piping to take proper safety measures and to always follow safe testing protocol.

Our Forensics team are experts in investigating almost any type of materials failure. To learn more about our materials science expertise and PVC pipe failures, visit our materials science webpage or reach out.